Product Information

Chemical Name:VINYLTRIETHOXYSILANE

Product Code:LT-151

Molecular Formula:C8H18O3Si

Molecular Weight:190.3

CAS NO.:78-08-0

Properties and Reactivity

LT-151 is a colorless transparent Liquid with aromatic odour. It is readily soluble in organic solvents such as common aliphatic and aromatic solvents.

LT-151 is a difunctional silane containing an unsaturated double bonded vinyl group and a hydrolysable inorganic ethoxysilyl group. Its reactive dual nature enables it to bond inorganic materials and organics organically.

→ Reactive in free radical chemistry

→ Reactive in hydrosilation chemistry

→ Forms siloxane crosslinks via moisture cure

→ Bonds with inorganic surfaces through alkoxysilane groups.

In the presence of moisture, LT-151 will hydrolyse living wave-producing silicone hydroxyl groups (hydrolysis activity is lower than that of LT-171), forming bonds on the surface of various inorganic materials.

Polymerisation and copolymerisation. vinyl groups in LT-151 can undergo free radical polymerisation.

Silicon-hydrogen addition reaction. vinyl groups in LT-151 can be bonded with silicon-hydrogen for silicon-hydrogen addition reaction.

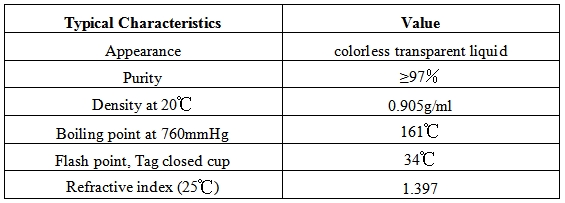

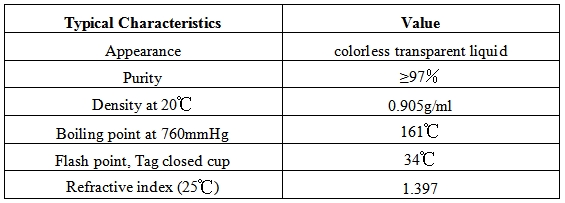

Technical Data

Note: the above data is for reference only, cannot be as a technical specification.

Application

For treatment of fillers

LT-151 can be used to improve the affinity of glass fiber, inorganic fillers and resin to react with vinyl, reinforced polyester resin.

Thermoplastics

LT-151 is commonly used in silane cross-linked polyethylene cables and pipes. During extrusion, LT-151 can be grafted onto the polymer by the action of a peroxide initiator, and this silane graft can be cross-linked by boiling in water, steam baths, or by absorbing moisture in the air, thus converting the original thermoplastic resin into a thermosetting resin. Silane crosslinked polymers have better heat resistance, mechanical strength, and chemical resistance than the original thermoplastic resins, such as XLPE, which is ideal for cable insulation and hot water pipe materials.

Silane coupling agent LT-151 is suitable for polyethylene copolymers of all complex shapes and densities, for greater processing tolerance, filled composites, etc. It has high service temperature, excellent resistance to pressure cracking, memory, abrasion and impact resistance.

Polymer modification

Polymer dispersions (e.g. styrene acrylics), modified with LT-151 show improved adhesion strength in wet conditions and wet scrub resistance.

Sealants

Silane coupling agent LT-151 is used in sealants to improve adhesion, chemical resistance, filler dispersion and ageing resistance by moisture-induced crosslinking. For example, in polybutadiene plastisols, LT-151 is used to treat the filler quartz powder to improve the surface three-way bonding between the polybutadiene resin and the quartz powder and to enhance the plastic densification, thus improving the moisture resistance of the plastisols.

LT-151 can be used to synthesise alkoxy capped silicone oils using the silicone hydrogen addition reaction to produce environmentally friendly Alkoxy RTV-1.

Water Repellents and Surface Protection

LT-151 is used as the surface moisture-proof treatment of electronic components, which can be used in the surface moisture-proof treatment of disc type fine-tuning porcelain dielectric capacitor and anti-high-voltage composite dielectric capacitor, to improve the moisture-proof performance of the product and surface finish, and to improve the qualification rate of the product.

鄂公网安备 42900402000406号

鄂公网安备 42900402000406号 Home

Home Tel

Tel Product

Product